Vehicle

Brake Information

Written By Michael Romano, Mechanical Engineer

Contents:

Page

Description

2 Pedal

Feel

4 Brake

Performance

5 Brake

Fade

6 Brake

Feel and its Benefits

7 Master

cylinder and caliper sizing effect on pedal feel

8 Stainless

Steel Braided Brake Lines

8 Stopping

Force Calculations

9 Lug

Nut Torque Effect on Brakes

9 Brake

Air Ducts

10 Rear

Brake Upgrades

11 Brake

Fluids (information

copied from multiple sources)

14 Brake

Bleeding/Flushing

15 2-Piece rotors

16

Warped Rotors and The Truth

17

Cross-drilled and Slotted Rotors

18 Brake

Caliper, fixed, sliding and multi-pistons

19 Dynamic

Brake Control (Panic Brake Assist)

19

Anti-lock Brake

Systems (ABS) (from:

http://www.geocities.com/nosro/abs_faq/

20

Glossary (from

http://www.stoptech.com/)

34 "Mini

brake test" For Fun

35

Appendix with

diagrams, charts and graphs

Little background

on me: I was a brake engineer working at Continental-Teves (trademark: Ate

Brakes) and Ford. The info below is meant to give you a better understanding

of brakes and many things in it are just for information purpose.

3 of the best brake info sites I've

ever found (don't agree with everything, but some things are subjective so

you can decide what you want)

http://www.stoptech.com/technical/

http://www.geocities.com/nosro/abs_faq/

http://www.dba.com.au/technical.asp

Pedal

Feel

First some quick

definitions: Brake Pedal ratio is the measurement of how much mechanical assistance

you are getting from the pedal. Example: a ratio of 4.1 will give you 41 pounds

at the booster input rod for a 10 pound load at the pedal itself.

Dead or lost travel

is how much pedal stoke is required before you actually start stopping.

Dead Travel or

Lost travel and overall poor pedal feel is made up of the following:

[(Travel as measured

at the brake service pedal assembly pin (where the booster connects)]

(Imagine traveling

from the pedal through the brake system to the rotor, all lost travel must

be multiplied by whatever your brake pedal ratio is.)

1. Tolerance between

brake pedal pin and booster input rod. This can be quite a bit for systems

that use a pin mounted brake light switch. If you do have such a switch do

not remove it or take up the slack as your brake lights will be on all the

time. If you don't have a pin-mounted switch just get a tighter bushing. If

you do, you're out of luck.

* will be felt

during first few mm of travel

2. Slack in the

brake pedal assembly itself. To see how good or bad yours is, with the car

off pump the brakes until hard (2-3 pumps) and then grab the pedal with your

hands and see how much it moves around.

* will be felt

through first few mm of travel (I hope)

3. Dash flex. This

can range dramatically from vehicle model to vehicle model. Not much you can

do about this.

*felt during medium

and high decelerations stops on most cars, on Fords dashes flex with the breeze

4. Lost travel

in booster. This is designed to be there to allow for booster expansion due

to climate and use over time. Only adds half an mm (multiplied by the pedal

ratio).

*felt only in the

first few mm of travel

5. Flex of booster

shell. Can be a real problem on some designs. All you can do is try and brace

the booster or replace with a better product.

*felt on medium

and high deceleration stops

6. Design tolerances

in the Master Cylinder. Varies greatly from one to another. Simply, if you

want less lost travel in the TMC (tandem master cylinder), you have to pay

for a more expensive one. A minimum lost travel of about 1-1.5mm is required

for proper and safe operation. However, I've seen some with double that. (Again

multiplied by the pedal ratio)

*felt during first

10mm or so of pedal travel

7. The brake tubes

and ABS unit. Maybe .0000001mm here. Don't worry about it.

8. Brake hoses.

Get steel braided ones, there worth it. Rubber hoses flex quite a bit under pressure.

*felt almost all

the time

9. Brake Caliper

Piston Roll Back. This is usually the worst offender. Only way to get rid

of this is to get better calipers. Roll back is how far the piston moves away

from the rotor when pressure is released. The bigger the gap, the more you

have to push on the pedal to get contact.

10. Caliper Deflection.

The caliper actually flexing under pressure, like 9 you can only improve this

with better calipers.

*felt during medium

and high deceleration stops

11. Brake pad backing

plate. If this is flimsy it will flex and not allow a good contact between

the rotor and pad forcing you to apply more pressure and therefore more pedal

travel. Fixed by replacing pads with higher quality ones.

*felt most of the

time

12. Brake pad material

itself. If the material is low density it will compress like a sponge. And

if it's a low mu (friction) pad it will require more pressure and therefore

more pedal travel.

*felt all the time

13. Rare, but a

problem on really cheap brake pads: The bonding process used to bond the brake

pad material to the backing plate. A poor process will cause the material

to "squirm" around.

Well those are

the biggies, but not the biggest. The biggest is AIR in the system. Before

you do anything else do a really good and thorough brake bleed. And only use

the fluid it says to use on the cap, DOT 3 or DOT 4 or whatever.

Also, changing

the brake pedal assembly to one with a lower ratio. Remember all lost travel

is multiplied by the pedal ratio, the lower the ratio the less dead travel

at the pedal pad. This also firms up the pedal as you're getting less mechanical

assistance. Just be careful, because if you're brake booster fails it will

take more force on the pedal to come to a stop.

Pedal feel can

also be "tuned" with a different booster.

Cut-in is what

sets the initial point of boost (when it kicks in)

2-stage (knee height)

is what sets how much initial force

Boost ratio is

just as it sounds, it sets how much assist you get

Run-out is the

maximum assist

By lowering the

cut-in and increasing the 2-stage you get a better initial bite sooner. Just

have to be careful you don't go overboard and have the driver eat the steering

wheel at every stoplight (like an '80s Audi).

Brake

Performance

Brake Performance:

Level of brake torque produced and the resistance to brake torque loss, better

known as fade.

Brake Torque=Fluid

Pressure*caliper piston area*pad coefficient of friction*rotor radius

-For piston area

multiply area by 2 for sliding calipers, rotor radius is measured from center

of rotor to the center of the pad

For performance

I do not use the term stopping distance because that involves more than just

the brakes.

I want to make

it clear there is a difference between making a brake system feel better and

actually perform better.

The stopping distance

of a car is not necessarily directly related to the feel. A poor feeling brake

system can have very good performance, i.e. Jaguar. While a great feeling

system can have lousy performance, i.e. Ford Focus

Basically, you

need a bigger rotors and good pads with the best contact patch possible between

the two. Also higher friction levels with higher mu brake pads.

And most importantly.........REALLY

GOOD TIRES!

And you need a

way to get rid of that heat at a faster rate. More rotor mass and/or better

conduction (vented, etc.).

How a car stops

is simple, it takes Kinetic Energy (energy created by motion) and transfers

it to Heat (Thermal) Energy. It does this by the mechanism of friction.

KE=1/2 the mass

of the vehicle multiplied by the square of it's velocity

Brake Power is

determined by the rate of KE to TE transfer, or also know as WORK.

Simply, to stop

sooner you need to transfer Kinetic Energy into Heat Energy faster.

There are no other

tricks; you need higher levels of friction and ways to dissipate the heat

quicker.

The big things

to do to get shorter stopping distance:

1. Best Tires for

the conditions (use common sense here, no Pilots in Feb in Alaska)

2. Higher Friction

Brake Pads and/or rotors

3. Bigger diameter

rotors

4. Calipers with

more piston area

The other things

you can do that give you that extra advantage:

1. LOSE WEIGHT

(the car I mean), less mass, less KE

2. Minimize rotational

inertia of wheels/tires. Get lighter wheels and tires (all else being equal).

Note: the farther away from the center of rotation the mass is the great the

inertia, so a 17" wheel will have greater inertia than a 16" all

else being equal.

3. Try and balance

out the braking, if the rears can do more work it spreads out the work. Less

weight transfer to the front BY MOVING THE BATTERY TO THE TRUNK, stuff like

that.

4. Practice! Get

to know how your system works so you can best utilize it.

5. Don't drive

to fast, remember it the square of the velocity. The amount of KE increase

from 40KPH to 80KPH is not 200%, but 400%

The formula below

is a decent way to estimate what, if any, increase you have in brake torque

after an upgrade:

Brake Torque Increase

%=

[(caliper piston

area new/old) * (effective radius new/old)* (brake pad friction coefficient

new/old)]

-effective radius

is the distance from the center of the hub to the center of the brake pad

-For sliding calipers

multiply the areas by 2

Any answer equal

to 1 means no increase. Any answer less than 1 means you've gone backwards.

Any answer greater than 1 means a torque increase.

This will NOT give

you the actual brake torque, just the difference.

Things like 2-piece

rotors, cross-drilling, slotting, cryogenics, heat-treating are all "at

limit" technologies. In other words they only make a noticeable difference

(if any) at the very limits. If you drive on the street in a manner that actually

utilizes these technologies regularly you're probably dead and not reading

this!

Brakes are as much

art as science, there are just so many different variables involving not only

performance but also feel and consumer wants it becomes a real pain!

Again, you have

to know what you want to get out of your system and where you're going to

use it.

In the end if you

got the cash it won't hurt, but you get to a point of diminishing returns

and you have to wonder!

Brake Fade

Brake fade: the

loss of brake torque due to items other than mechanical failure

Basically, fade

is caused by over use of the brakes to the point where a majority of the fluid

pressure and/or pad friction is lost.

This is caused

by heat, as heat is created in the brake system it causes the brake fluid

to boil and that introduces air into the system.

If enough brake fluid is transformed into a gas you will not be able

to create the required brake pressure to stop the vehicle.

On top of this

the same heat causing the fluid to boil is also breaking down the pad and

dropping its coefficient of friction. This

is commonly referred to as pad fade.

To avoid fade is

very easy, you can use a fluid with a higher boiling point and/or a pad with

a more advantageous temperature vs. coefficient of friction curve. You can also introduce cooling into the system

with brake air ducts, vented rotors, rotors with more vent surface area and

overall better ventilation in the corner area.

Also, venting built

up gases under the pad was a big problem, but pad tech has come so far that

it's not something I would worry about (assuming your using race pads for

racing). Again it's one of those things that are there but only makes a very,

very, very minor difference (if any) most of the time.

Brake

Feel and it’s Benefits

Brake feel: pedal

effort and pedal travel for any given desired deceleration. Ease of brake

pressure modulation, accuracy and precision of modulation. Feedback through

the pedal "describing" pad rotor contact dynamics and pressure fluctuations.

Benefits of "better"

feel:

Brake feel is just

like steering feel. The better the feel/feedback is the more of the inherent

performance you will actually be able to use.

Imagine a car that

has 1.0g of lateral grip, but has lousy steering. Too light, completely dead,

nothing happens just off-center, poor linear response and too much or too

little ratio.

How much of that

great 1.0g are you ever going to be actually using with poor steering?

Same with brakes.

Improving feel will allow you to better use what you have.

However, it will

not objectively increase brake performance. If you are already getting the

max out of you system then better feel will not get you more.

Things like steel

lines, stiffer calipers affect feel, not performance. Only force applied,

torque arm and friction do that. You can change things like lines, calipers,

pedals and boosters to change the characteristics. Such as, initial bite point

and initial deceleration level, pedal travel and effort, pedal force multiplication.

However, these do not actually produce more brake torque.

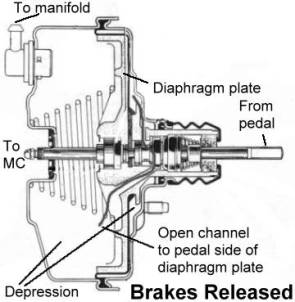

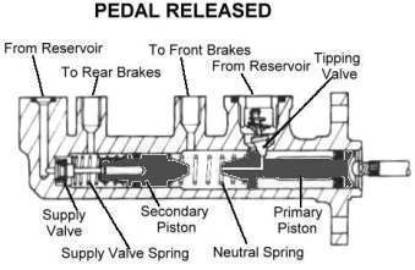

What

master cylinder and caliper sizing means to pedal feel

Here is how to calculate mechanical

advantage:

Area of MC * pedal ratio = M

Area of front piston= N

ME= M/N = larger is less effort

(MC-master cylinder)

A larger MC results in...

> less pedal travel

> a higher effort pedal

> less hydraulic advantage

> Works well on vehicles that have high fluid volume requirements

since you can get plenty of flow with reasonable pedal travel.

Large bore master cylinders tend to give less “feedback” and a somewhat

isolated feel.

A smaller MC results in...

> more pedal travel

> a lower effort pedal

> more hydraulic advantage

> Works well in lighter vehicles

where fluid volume requirements is low and excessive pedal travel is not a

concern. Small bore master cylinders

tend to give better “feedback” and less isolation from the system.

As you can see there's more advantage

to a smaller bore MC, but some heavy trucks require the fluid only a big bore

MC can provide.

Typical TMC, Tandem Master Cylinder,

most common design used

Caliper:

Larger caliper

piston area results in...

> more pedal

travel

> a softer pedal

> more hydraulic

advantage

Smaller caliper

piston area results in...

> less pedal

travel

> a firmer pedal

> less hydraulic

advantage

Stainless

Steel Braided Brake Lines

SS lines will NOT

improve braking distance.

What will SS lines

do? They will firm up the pedal and will shift the braking pedal feel curve.

The later means that you will reach braking force earlier in the pedal stroke

than without the SS lines.

Anyway, SS lines

do technically firm up the pedal through out the brake pedal stroke. But the

difference may not be noticeable all the time.

SS lines almost

always make a difference at braking events at or over 0.25g, this is equivalent

to the kind of hard braking you see when driving back roads in an aggressive

manner. Regular rubber brake hoses

will flex initially under high pressure, this is a volume loss that is expressed

as dead travel at the pedal.

With SS lines the

harder you push on the pedal the more the level of the improvement felt.

![]()

Stopping Force:

Equations: (for

ease and consistency try and use meters and kg)

NOTE: Equation 1 does not mean more weight you have more

stopping force, it is just to calculate the stopping force required. As you can see in Equation 2, the larger the

stopping force is the larger and more aggressive the brakes need to be or

can be.

1.

stopping force

total = weight of car * longitudinal coefficient of friction of tires

2.

Front Force = weight

front + total weight * tire friction * height of CG * (1/wheel base)

3.

Rear Force = weight

rear - total weight * tire friction * height of CG * (1/wheel base)

4.

% front = Front

Force/Stopping Force

5.

% Rear = Rear Force/Stopping

Force

6.

Area of MC * pedal ratio = M

Area of front or rear piston= N

Mechanical Force Ratio= M/N

7.

mechanical force

ratio front = mechanical force ratio * %front

mechanical force

ratio rear = mechanical force ratio * %rear

8.

Stopping Force

= pedal force * brake pad coefficient of friction * mechanical force ratio

* (1/radius of the tire) * brake rotor effective radius

.....solve for

the parameter you need

Lug

Nut Torque

Over-torque of

wheel lug nuts is one of the prime causes of brake rotor distortion. This

can lead to permanent warping of the rotors, uneven wear of the rotors and

pads and lots of brake chatter (NVH).

With today's very

stiff alloy wheels, like from BBS, SSR, Volk, etc., when you torque down the

lug nuts the wheel-mounting surface will force what ever it contacts to take

its shape. Which means whatever that surface looks like will be what the rotor

looks like.

Get a torque wrench

and check the torques on every lug nut and make sure they are within the specs

(which you should be able to find in your owner's manual). And make sure that

every lug nut is torqued down exactly the same. Even if all 5 on a wheel are

within specs, not having all 5 be equal will introduce distortion.

And if you think

that your light alloy wheel can't possibly be that stiff, you wrong they are

MUCH stiffer than the brake rotor or even the hub.

WORD OF CAUTION:

Don't assume that torque the lugs to the lowest range in the spec is the best.

Try and keep it nominal not at the extremes of the range.

Much of the problems

with rotor warp, brake chatter, disk thickness variation can be traced back

to over-torque and uneven torqued lug nuts.

After coming back

from the shop, get that torque wrench and check the lug nuts yourself.

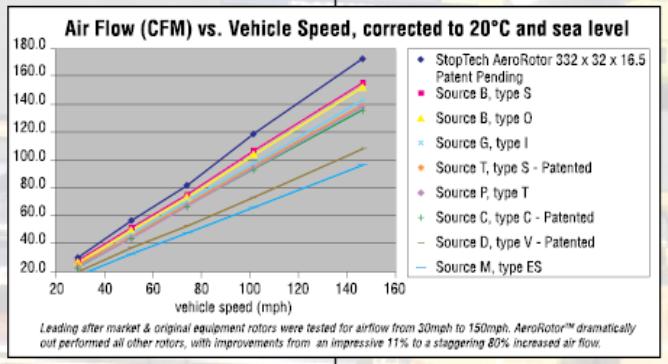

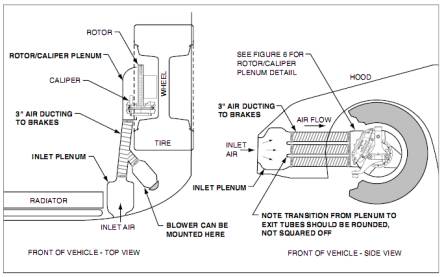

Brake Air Ducts

This is only for

auto-x and racing.

Getting all that

extra air on the brakes going down a straight gets the brakes nice and cool

for the next corner.

Cheap and effective

way to keep rotor temperatures down and therefore reduce fade.

Rear

Brakes

Just want to add

a little warning about the rear brakes. Be VERY careful when it comes to making

changes back there. Upgrading the rears to increase braking power, not just

feel, can be a double-edged knife.

More braking power

to the rears will only do you well if; 1. the balance is woefully off and

the rears are under-utilized, if you can easily lock-up the rears your already

at full potential or 2. you have increased the weight the rear tires carry,

the grip of the rear tires and/or minimized the weight transfer to the front.

Putting more powerful

brakes on the rear alone do nothing more than cause you to lock up or go into

an ABS event sooner. You must increase the rear tires load to benefit from

an increase in the rear brakes power. Otherwise, the rears should be looked

at only from a "feel" standpoint.

Brake

Fluids

Common Brake Fluid

Boiling Points

|| Wet Boiling Point || Dry Boiling Point

Castrol SRF || 518°F || 590°F

Earl's HyperTemp

421 || 421°F || 585°F

Motul 600 || 420°F || 593°F

AP-600 || 410°F

|| 572°F

Neosynthetic 610 || 421°F || 610°F

ATE-Super Blue

|| 392°F || 536°F

Valvoline || 333°F || 513°F

Castrol LMA || 311°F || 446°F

Earl's HyperTemp

300 || 300°F || 568°F

Ford HD || 290°F

|| 550°F

Wilwood 570 || 284°F || 570°F

PFC-Z rated || 284°F || 550°F

AP-550 || 284°F

|| 550°F

All brake fluids

absorb moisture, some faster than others (except silicone which is not recommended

for anti-lock brake systems). Castrol SRF resists moisture contamination (non-hygroscopic)

more than any other fluid we tested; therefore change intervals can be greatly

extended. This reduces the effective cost over a season of racing. Many drivers

say that they can run the same fluid all year long with only bleeding off

the fluid in the calipers for each event. This way a can or two will last

all year. Other fluids (hygroscopic type) require additional flushing of the

system for each track event to maintain the lowest percentage of moisture

and the highest boiling point.

FYI - The Castrol

SRF is around $77/container versus $10-15/container for the rest.

Silicone Brake

Fluids

Fluids containing

Silicone are generally used in military type vehicles and because Silicone

based fluids will not damage painted surfaces they are also somewhat common

in show cars.

Silicone-based

fluids are regarded as DOT 5 fluids. They are highly compressible and can

give the driver a feeling of a spongy pedal. The higher the brake system temperature

the more the compressibility of the fluid and this increases the feeling of

a spongy pedal.

Silicone based

fluids are non-hygroscopic meaning that they will not absorb or mix with water.

When water is present in the brake system it will create a water/fluid/water/fluid

situation. Because water boils at approximately 212º F, the ability of the

brake system to operate correctly decreases, and the steam created from boiling

water adds air to the system. It is important to remember that water may be

present in any brake system. Therefore silicone brake fluid lacks the ability

to deal with moisture and will dramatically decrease a brake systems performance.

Brake Fluid and Cold Temps.

Kinematic

viscosities: All brake fluids (DOT 3, DOT 4 and DOT 5) must meet a minimum

viscosity test of not less than 1.5 centistokes at 100° C (212° F) and must

not be more than the following to meet their various classifications (the

larger numbers indicate higher kinematic viscosities just like with motor

oils).

DOT 3 1500 Centistokes at minus 40° C

DOT 4 1800 Centistokes at minus 40° C

DOT 5 900 Centistokes at minus 40° C

Higher kinematic viscosities means it "flows easier" at the cold

temps.

A centistokes is 1 mm^2/s

MINIMAL boiling points

for these specifications are as follows:

|| Dry Boiling Point ||

Wet Boiling Point

DOT 3 || 401ºF || 284ºF

DOT 4 || 446ºF || 311ºF

DOT 5 || 500ºF || 356ºF

DOT 5.1 || 518ºF || 375ºF

Poly Glycol Ether

Based Brake Fluids

Fluids containing

Poly glycol ethers are regarded as DOT 3, 4, and DOT 5.1. These type fluids

are hygroscopic meaning they have an ability to mix with water and still perform

adequately. However, water will drastically reduce the boiling point of fluid.

In a passenger car this is not an issue. In a racecar it is a major issue

because as the boiling point decreases the performance ability of the fluid

also decreases.

Poly glycol type

fluids are 2 times less compressible than silicone type fluids, even when

heated. Less compressibility of brake fluid will increase pedal feel. Changing

fluid on a regular basis will greatly increase the performance of the brake

system.

FLUID SPECIFICATIONS

All brake fluids must meet federal standard #116. Under this standard are

three Department of Transportation (DOT) minimal specifications for brake

fluid. They are DOT 3, DOT 4, and DOT 5.1 (for fluids based with Polyalkylene

Glycol Ether) and DOT 5 (for Silicone based fluids).

Wet vs. Dry Boiling

Point

WET BOILING POINT

- The minimum temperatures that brake fluids will begin to boil when the brake

system contains 3% water by volume of the system.

DRY BOILING POINT

- The temperatures that brake fluid will boil with no water present in the

system.

How does water

get in there?

Water/moisture

can be found in nearly all brake systems. Moisture enters the brake system

in several ways. One of the more common ways is from using old or pre-opened

fluid. Keep in mind, that brake fluid draws in moisture from the surrounding

air. Tightly sealing brake fluid bottles and not storing them for long periods

of time will help keep moisture out. When changing or bleeding brake fluid

always replace master cylinder caps as soon as possible to prevent moisture

from entering into the master cylinder. Condensation, (small moisture droplets)

can form in lines and calipers. As caliper and line temperatures heat up and

then cool repeatedly, condensation occurs, leaving behind an increase in moisture/water.

Over time the moisture becomes trapped in the internal sections of calipers,

lines, master cylinders, etc. When this water reaches 212º F the water turns

to steam. Many times air in the brake system is a result of water that has

turned to steam. The build up of steam will create air pressure in the system,

sometimes to the point that enough pressure is created to push caliper pistons

into the brake pad. This will create brake drag as the rotor and pads make

contact and can also create more heat in the system. Diffusion is another

way in that water/moisture may enter the system.

Diffusion occurs

when over time moisture enters through rubber brake hoses. The use of hoses

made from EPDM materials (Ethlene-Propylene-Diene-Materials) will reduce the

amount of diffusion OR use steel braided brake hose with a non-rubber sleeve

(usually Teflon) to greatly reduce the diffusion process.

DOT what?

DOT: Acronym for

"Department of Transportation" -- an American federal agency or

"Department of Transport" -- a British agency

DOT 3: This brake

fluid has a glycol base. It is clear or light amber in color. Its dry boiling

point is 401° minimum and wet boiling point of 284° minimum. It will absorb

1 to 2 percent of water per year depending on climate and operating conditions.

It is used in most domestic cars and light trucks in normal driving. It does

not require cleaning the system and it can be mixed with DOT 4 and DOT 5.1

without damage to the system. The problem with it is that it absorbs moisture

out of the air and thereby reduces its boiling point. It can also damage the

paint on a vehicle.

DOT 4: This brake

fluid has a borate ester base. It is clear or light amber in color. Its dry

boiling point is 446° minimum and wet boiling point of 311° minimum. It is

used in many European cars; also for vehicles in high-altitude, towing, or

high-speed braking situations, or ABS systems. It does not require cleaning

the system and it can be mixed with DOT 3 without damage to the system. The

problem with it is that it absorbs moisture out of the air and thereby reduces

its boiling point. It can also damage the paint on a vehicle.

DOT 5: This brake

fluid generally has a silicone base. It is violet in color. Its dry boiling

point is 500° minimum and has no wet boiling point in federal DOT 5 specifications.

It is used in heavy brake applications, and good for weekend, antique, or

collector cars that sit for long periods and are never driven far. It does

not mix with DOT 3, DOT 4, or DOT 5.1. It will not absorb water and will not

damage the paint on a vehicle. It is also compatible with most rubber formulations.

The problem with it is that it may easily get air bubbles into the system

that are nearly impossible to remove, giving poor pedal feel. It is unsuitable

for racing due to compressibility under high temperatures. If as little as

one drop of water enters the fluid, severe localized corrosion, freezing,

or gassing may occur. This can happen because water is heavier and not mixable

with silicone fluids. It is unsuitable for ABS.

DOT 5.1: This brake

fluid has a borate ester base. It is clear or light amber in color. Its dry

boiling point is 500° minimum and wet boiling point of 356° minimum. It is

used in severe-duty vehicles such as fleets and delivery trucks, towing vehicles,

and racecars. It can be mixed with DOT 3 or DOT 4 without damage to the system.

It maintains higher boiling point than DOT 3 or DOT 4 fluids due to its higher

borate ester content. It is excellent for severe duty applications. The problem

with it is that it costs more than other fluids and there is limited availability.

It also absorbs moisture out of the air and thereby reduces its boiling point.

It can also damage the paint on a vehicle.

What causes a mushy

pedal?

DOT 5 fluid is

not hygroscopic, so as moisture enters the system, it is not absorbed by the

fluid, and results in beads of moisture moving through the brake line, collecting

in the calipers. It is not uncommon to have caliper temperatures exceed 200°

F, and at 212° F, this collected moisture will boil causing vapor lock and

system failure. Additionally, DOT 5 fluid is highly compressible due to aeration

and foaming under normal braking conditions, providing a spongy brake feel.

Brake

Bleeding/Flushing

One thing that

is ALWAYS true never let the TMC (master cylinder) on an ABS, traction control

(TCS) or electronic stability program (ESP) car run dry. You'll never get

the air bubbles out again by hand. To be honest there is more than one right

way and if you found something that works, why fix what's not broken.

Just FYI-

At the factory

this is how it's done. They do it all one shot.

First you mount

the Evac-Fill head unit to the reservoir then all air is evacuated from the

system, creating a vacuum. Then fluid is forced through the system at high

pressure.

Then the car is

delivered and people complain about mushy pedal!

Just some more

stuff:

I e-mailed a Tech

at Ford I used to work with on the proper bleed sequence. Since techs do these

all the time and engineers don't I'll take his advice.

This is it:

Doing nearest or

most distant doesn't matter. What matters is if the brake system is a diagonal

or front-rear system.

Quick definition:

diagonal means that one circuit in the master cylinder feeds the front driver's

side and the rear passenger side. The other circuit the front passenger's

and rear driver's. Both circuits are of equal volume. Front-Rear means that

one circuit supplies the front calipers, while the other the rear calipers.

The Primary circuit (front caliper circuit) is of greater volume.

All you need to

do is make sure you do the circuits together. For instance, on most passenger

cars it's a diagonal system. So you want to do the driver's front and passenger's

rear together, which you do first is not all that important. But he does agree

that the tradition is to do the rear first. Or best to get a friend and do

both at the same time. And take your time (he told me to make sure I added

this).

Same holds true

for the Front-Rear systems. Do fronts together and rears together. Usually

only trucks, SUVs and very heavy front bias cars (Ford Crown Vic) have a Front-Rear

system.

Just FYI- Diagonal

is used so that if one circuit fails the vehicle is still stoppable in a stable

manner as at least one front and rear wheel is braking and on opposite sides.

Front-Rears are used on heavy, front-bias cars require a lot of volume up

front.

ABS Bleeding:

Do 3 normal bleeds

and then do

An ABS stop if

you still feel that air might be trapped. Then do 1 more

Bleed. The ABS

stop would have flushed the air out.

2-Piece rotors

I have seen a lot

on 2-piece rotors. Some of the information contained in them is correct some

is mythical.

Some definitions.

2-Piece rotor:

A brake disc rotor that has a separate hat (cap) usually made from a lightweight

metal. There are two types of common 2-piece street rotors. One uses a bolted

hat and the other a pinned hat (also known as a "floating rotor"

design).

The bolted type

is just what it sounds like. Usually an aluminum hat bolted to a cast iron

rotor. The only real benefit of this design is weight savings. However, weight

savings tend to be only 10-20%, all else being equal, but with a 50-75% price

increase.

The pinned type

has usually stainless steel pins that attach the aluminum hat to the rotors.

This allows the rotor to "float" on the pins. The great advantage

of this design is that it allows the rotor to move freely. When the rotor

expands and contracts there is much less chance of binding or distortion.

As you can imagine this cuts down on warping and uneven wear (DTV). The disadvantage

of this design is really high costs and increased NVH.

As far as better

heat conduction, not really. It does help a bit, buts it's not enough to make

it worth the extra cost. The nice think about the weight savings is you can

get a larger rotor with out taking a weight penalty.

- It may help keep

your wheel bearings cooler.

My opinion:

2 piece floating

(pinned) rotor is worth every penny. This is good technology, yeah they cost

a ton but they do the job. They keep

the rotor even through out operating temperature range and they keep down

DTV problems better than anything I've ever seen.

Be sure they're the pinned hat type and not the bolted hat type.

Warped Rotors

Note: DTV stands

for disk thickness variation, caused by uneven rotor wear and/or pad material

deposited on the rotor. Pad deposit usually happens when brakes are hot and

you let them "sit cool"; you should drive around at slow speeds

while your brakes cool.

Warped Rotor:

Cut an imaginary

plane through the center of the disc part of the rotor that is parallel to

both surfaces of the disc, this is done when rotor is new.

If the rotor is

warped this imaginary plane (now part of the disc) will no longer be parallel

to a reference plane, that reference plane was also parallel to both surfaces

of the disc when the disc was new.

In essence a warped

rotor is a rotor that is deformed throughout its thickness.

A rotor with DTV

(surface imperfection) issues:

The imaginary plane

above is still parallel to the reference plane mentioned in the warped rotor

definition, however the two surfaces of the disc are no longer parallel to

each other.

Think of 2 identical

planks of wood.

1st plank you take

a planer to it in a haphazard way to the surface making the surface wavy.

This is a surface condition.

You can sand the

surface down to get back to a smooth surface.

2nd plank you steam

heat and then bend around a steel pipe. This plank is warped. You can sand

all you want, but you'll never get it straight again.

You can see why

it's so easy to mistake one for the other; on the surface it all looks "warped"

Of course if the

rotor is too thin then it can't be "sanded" smooth, but a warped

rotor can't be turned no matter how thick it is.

Cross

Drilled and Slotted Rotors

Cross-drilled rotors:

Disks

that have been drilled through with a non-intersecting pattern of radial holes.

The objects are to provide a number of paths to get rid of the boundary layer

of out gassed volatiles and incandescent particles of friction material and

to increase "bite" through the provision of many leading edges.

The advent of carbon metallic friction materials with their increased temperatures

and thermal shock characteristics ended the day of the drilled disc in professional

racing. They are still seen (mainly as cosmetic items) on motorbikes and some

road going sports cars. Typically in original equipment road car applications

these holes are cast then finished machined to provide the best possible conditions

by which to resist cracking in use. But they will crack eventually under the

circumstances described in another section (see Cracking). Properly designed,

drilled discs tend to operate cooler than non-drilled ventilated discs of

the same design due the higher flow rates through the vents from the supplemental

inlets and increased surface area in the hole. That's right, inlets, the flow

is into the hole and out through the vent to the OD of the disc. If discs

are to be drilled, the external edges of the holes must be chamfered (or,

better yet, radiused) and should also be peened.

Slotted:

Shallow, sharp edged but radiused bottom grooves milled into cast iron discs to provide leading edges for bite and a path for the fire band of gases and incandescent friction material to be dissipated through. If the slots fill up with pad material, the system is operating at too high a temperature.

For the track they

work. Not as dramatically as the ads

will lead you to believe, but they do a good job of keeping the pad surface

"clean" when they get really hot and they do a good job of venting

gases. Again though, with modern pads

neither of the issues mentioned are that severe now a days.

Brake Calipers

The caliper’s basic

function is to force the pads against the rotor. A caliper is made of 3 basic groups, the housing

(body), the pistons and the mounting bracket. The pistons sit in the housing and are the components that directly

push the pads against the rotor. The

housing is there basically to hold and flow fluid to the pistons and give

the piston somewhere to live.

There are 2 families

of calipers, the sliding caliper and the fixed caliper:

The sliding caliper

is by far the most common and is mostly likely what’s on your car. It has pistons only on the inboard side and

the caliper slides on guide pins to force the outside pad against the rotor.

The fixed caliper

has a single (monobloc) or 2 piece bolted housing and piston(s) on both the

outboard and inboard side. The caliper

is completely stationary and each side applies pressure to the pads independently.

What’s the difference?

The major differences between the fixed and sliding calipers is weight

and stiffness. A fixed caliper in general weighs less and

has significantly less flex. This

means better pedal feel. Fixed calipers

also tend to have a lower profile allowing a larger rotor in the same wheel. Advantage of a sliding caliper is cost, they

are usually much less expensive.

Single piston and

multi-piston Calipers:

Most sliding calipers

are of the single piston type, which means one large piston does all the work.

Dual-piston calipers are becoming more popular.

Most fixed calipers are 4 piston type, 2 pistons on each side. There are 2 piston fixed and some go as high as 8 pistons total.

The advantages

of multiple pistons is:

1. More piston

area more force on pad and you can fit more piston in any given rectangle

with smaller diameter pistons (like engine valves in the heads).

2. A lower profile

caliper as 2 small pistons have a “lower height” than one big piston.

This means less flex since the distance from the point of application

to the bridge (top strap) of the caliper is less.

More pistons usually adds more cost

and low force braking feel is softer.

Dynamic Brake Control

Is a "Panic

Assist Feature" what it does is measure the velocity of pedal travel

by using either a sensor on the pedal or in the booster. If a certain threshold

is met then the booster (if it's an electronic booster) or the DSC pump will

apply max pressure. It doesn't actually stop the car in any shorter distance

than you could.

The reason for

DBC is that it's been established than many people when emergency braking

will ease off the brake pedal a little after the initial stab. DBC keeps the

pressure up even if you let off. This can be a real pain when your trying

to modulate the brakes yourself as most systems have a pretty low threshold

and just aggressive braking is seen as a "panic stop."

This feature also

requires a functioning ABS, the expensive systems are electronic so if the

ABS fails the feature is disabled, but some cheaper cars have a purely mechanical

system and a failed ABS is not detected. You can imagine what happens when

you have max brake power and no ABS.

Anti-Lock Brakes

Please go to this website: http://www.geocities.com/nosro/abs_faq/

|

Glossary of

Braking Terminology By Stephen

Ruiz, Engineering Manager ABS: Acronym for Anti-Lock Braking

system. Anti Lock braking systems sense the speed and rate of deceleration

of each of the wheels of a vehicle independently and, through a microprocessor

control system, act to prevent lock up of any of the tires under braking

force by cycling the line pressure to the wheel that is approaching

lock up. Most current passenger cars are fitted with ABS.

Braking efficiency: The ratio of actual deceleration

achieved on a given surface compared with the theoretical maximum.

Caliper: The "hydraulic clamp"

portion of a disc brake system. Manufactured from either ferrous or

non-ferrous material and bolted firmly to the suspension upright (or

"knuckle") the caliper holds the pads in place and, through

the action of hydraulic pistons actuated by the master cylinder, forces

them against the rotating surface of the disc when pressure is applied

to the brake pedal. 1. Fixed caliper: A brake caliper

in which two or more pistons are arranged on either side of a rigid

body with the disc in the center. Due to its inherent stiffness the

fixed caliper is the only design suitable for racing categories where

it is allowed and is the preferred design for high performance cars.

2. Floating caliper: A design in

which a single or dual piston is located inboard of the disc and the

outer body of the caliper slides on suitable surfaces in reaction

to piston pressure. The piston forces the inboard pad against the

disc while the sliding outer body clamps the outboard pad against

the disc. The inherent lack of rigidity in the design, compared to

fixed caliper design, combined with the friction inherent in the sliding

outer body makes this design less suitable for racing and high performance

use. The design is well suited for use with front wheel drive as the

absence of any outboard pistons allows greater negative (inward) wheel

offset. In all applications, this caliper type is simpler to manufacture

and affords more packaging flexibility for zero or even negative scrub

radius front suspension designs. It is sometimes used in the rear

on an application that has a fixed design in the front. 3. Open caliper: The design of

fixed caliper in which the "window" through which the pads

are inserted is structurally open. This design, while less expensive

to manufacture, significantly reduces caliper rigidity. 4. Closed caliper: The design of

fixed caliper in which the "window" through which the pads

are inserted is structurally reinforced by a bridge. 5. Caliper bridge: The structural

reinforcement across the open face of a fixed caliper. In order to

be effective the bridge must be rigidly bolted in place with high

tensile fasteners. Sliding - see Floating Caliper

Carbon metallic: This is a trademark of the Performance

Friction Corporation. Pad friction compounds containing large percentages

of pure carbon along with various metallic elements. Pioneered by

Performance Friction Corporation these compounds offer very constant

coefficients of friction vs. temperature characteristics along with

increased thermal capacity. The disadvantage is that, since they both

operate at higher temperatures and their temperature rises to operating

temperature faster than other compounds, they increase thermal shock

to the disc and increase thermal conduction to the caliper pistons

and brake fluid. As a result, it is recommended to not use drilled

discs with carbon metallic pads. Cast iron: Metallic iron containing more

than 2% dissolved carbon within its matrix (as opposed to steel which

contains less than 2%)and less than 4.5%. Because of its cost, relative

ease of manufacture and thermal stability cast iron (sometimes referred

to as "gray cast iron" because of its characteristic color,

but is actually a more specialized material for brake applications)

is the material of choice for almost all automotive brake discs. To

work correctly, the parts must be produced at the foundry with tightly

monitored chemistry and cooling cycles to control the shape, distribution

and form of the precipitation of the excess carbon. This is done to

minimize distortion in machining, provide good wear characteristics,

dampen vibration and resist cracking in subsequent use.

Disc: The rotating portion of a disk

brake system. Mechanically attached to the axle, and therefore rotating

with the wheel and tire the disc provides the moving friction surface

of the system while the pads provide the stationary friction surfaces.

Except for racing, discs are normally manufactured from one of several

grades of cast iron. Some European front drive passenger cars, where

the rear brakes do very little work, are using aluminum metal matrix

rear discs to save weight. Most professional racing cars use carbon/carbon

discs.

3. Solid disc: A disk cast as a

solid piece suitable for light cars not subjected to extreme braking.

Dust boots: Rubber shields that fit over the

exposed portion of the caliper pistons to prevent the ingress of dust

and road crime. As no known rubber compound will withstand the temperatures

generated by racing brakes, dust boots are not used in racing and

should be removed before truly hard driving for extended periods.

Effective temperature range: The range of operating temperatures

within which a pad material remains effective. As with coefficient

of friction, this should be used for comparative purposes only as

measurement procedures very between manufacturers and pad temperatures

are strongly affected by disc mass and rate of cooling.

Fireband: The name given to the boundary

layer of out gassed volatiles and incandescent particles of friction

material that rotates with the disc.

Modulation: The term given by the process

by which the skilled driver controls the braking torque to maintain

maximum retardation without locking wheels. Because the human being

modulates most efficiently by force rather than displacement, effective

brake modulation requires minimum pedal travel and maximum pedal firmness.

OE: This is an abbreviation for Original

Equipment. Please see the section "Original Equipment".

Sometimes it is used as an abbreviation to refer to the Original Equipment

Manufacturer (but more correctly referred to as the OEM).

Off brake drag: A condition in which the caliper

pistons do not fully retract when line pressure is released. Off brake

drag increases temperature and wear while decreasing acceleration,

top speed and fuel mileage. It is caused by either non-optimum seal

design, seals that have been hardened by thermal stress or excessive

disc run out.

Plot shape: The shape of the friction plot

during a long brake application it is easier and more efficient for

the driver to add pedal pressure than to remove it. Therefore the

easiest pad to modulate exhibits a high initial bite followed by a

gradual decrease in coefficient throughout the stop. If the level

of friction rises throughout the stop, brake modulation will be very

difficult.

Reservoir: The container in which brake fluid

is stored to provide a source of fluid for the master cylinder(s).

The reservoir must have sufficient volume to allow fluid displacement

equivalent to wearing the pads down past the backing plates. It must

also be sealed to prevent the absorption of moisture by the highly

hygroscopic brake fluid. Typically the reservoir cap is fitted with

an electrometric bellows open to atmosphere but sealed from the fluid.

1. Disc: Shallow, sharp edged but

radiused bottom grooves milled into cast iron discs to provide leading

edges for bite and a path for the fire band of gases and incandescent

friction material to be dissipated through. If the slots fill up with

pad material, the system is operating at too high a temperature. 2. Pad: Radial grooves molded or

cut into the surface of the pad to provide a path for fire band dissipation

and to double the number of leading edges and improve bite. Some long

pads also have a longitudinal groove.

Thermal shock: Disc materials, particularly cast

iron are degraded not only by the magnitude of temperatures reached,

but also by the "delta" temperatures the speed at which

the temperature increases and decreases. Cracks are largely caused

by weakening of the bonds between the grains of the metal brought

about by rapid change in temperature.

|

"Mini brake

test"...(I no longer own the 328i)

2 friends and me

performed a little brake test this morning.

I have a friend

that works at a small airport and was able to gain access to a nice flat and

large area. Not a runway.

We brought my 2000

BMW 328i with sport package and new WRX.

Atmosphere Conditions

at the time (benefit of being at an airport):

Temp: 54 F, Humidity

55%, Barometer 30.28in and rising, Wind 6 MPH East, partly cloudy

Surface was perfectly

dry and smooth. Surface was concrete.

The vehicles:

2002 Impreza WRX

Sportwagon with manual transmission, SSR Competition wheels, 225/45ZR17 Bridgestone

Potenza S-03 PP tires, Tein H-Tech springs, rear 20mm anti-roll bar. All else

stock, including brakes.

2000 BMW 328i with

manual transmission and the sport package, all stock. The tires: 225/45ZR17

Michelin Pilot Sports.

The WRX tires have

650 miles on them; the BMW tires have 7000 miles on them. All pressures where

set at the recommended settings as posted on the driver's doorjamb.

WRX has 720 miles

on the pads; the BMW has 7000 miles on the pads.

Some important

numbers on the BMW:

Curb Weight: 3197lbs,

Weight distribution front/rear: 50.5/49.5, brake setup: single piston sliding

calipers front and rear with 11.8 inch front rotor and 11.6 rear rotor both

ventilated.

Some important

numbers on the WRX Sportwagon:

Curb Weight: 3165lbs,

Weight distribution front/rear: 58.5/41.5,

brake setup: dual

piston sliding caliper up front and single piston sliding caliper in the rear

with 11.4 ventilated rotor in front and 10.3 inch solid rear rotor.

Test procedure:

10 consecutive

stops from 60MPH (using the car's speedometer, so chances are it wasn't exactly

60MPH). That's all I had the time to do.

Consecutive means

the time it took to turn around get back to the start and then 30 second wait.

3 drivers. Myself,

worked as a brake engineer and have experience. Driver 2 is a "car guy"

and knows how to drive. Driver 3 is good driver but not a "car guy."

All numbers are

rounded to nearest whole number, so no 120.5 feet, that would be listed as

121 feet. I do this because of the nature of the test and the measuring equipment.

Which consists of 10 cones spaced 15 feet apart and a tape measure.

The BMW's DSC (ESP

system) was turned off, so both cars had ABS only working.

For time reasons

I was the only driver to do all 10 runs.

The results (all

in feet):

------------------------WRX----------------------BMW

Run 1.......................121............................117

Run 2.......................121............................116

Run 3.......................121............................116

Run 4.......................123............................117

Run 5.......................125............................117

Run 6.......................125............................119

Run 7.......................128............................121

Run 8.......................133............................121

Run 9.......................133............................121

Run 10......................133............................121

Take these numbers for what their worth. Please keep

in mind the difference in tires and miles on them. And the "test equipment"

used. Disclaimer: This is for entertainment purposes only.

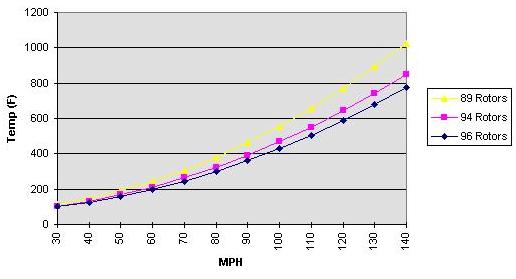

Appendix

Typical Temperature Curve for a Rotor

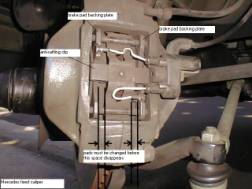

Typical Front

Brake Setup

Typical Rear Brake Setup