Front Seat Fixes

by Richard

Cousins 2003-04-21 (1998 - 540i) with acknowledgements to Jim Cash and

others.

The posting at bmwtips.com by "Lefty" provides a very good guide to the steps

for really getting stuck into the front seat frame.

The only additions to that are:

- if you are removing the driver's seat, make sure the steering wheel is

fully forward before you start

- after fully lowering the headrest, place the seat back at around 60

degrees for best manoeuvring throuigh the (front) door

- place a towel or some other protective material over the door sill and

front of the B pillar

- do NOT turn the ignition on after disconnecting power from the seat

as this will trip the SRS warning light which has to be reset by a dealer

- in fact it is a very good idea to disconnect the battery before

disconnecting power from the seat

- when reconnecting the seat wiring, double checking that the sliding

connector has fully clicked into place, before reconnecting the battery.

I needed to replace a (broken) foam pad on the seat bottom and for this I

found a very helpful posting by "Salts" on the E38 message board and which I

have reproduced

here.

Fixes without removing the front seat

There is quite a bit of reference

to use of "jaws" to fix front seat noises and there is a good chance that many

noises can be fixed without removing the front seats. What you

will need are:

- "sliding jaws" - part number 54 12 8 105 582 - two for each seat

- T-40 and T-45 torx bits or Allen keys (make sure they are forged, rather

than cast, and not the 'tamperproof' style which are too weak

- some self-adhesive velcro strips

- a hot melt gun with glue

- light foam (say 1/4 inch thick)

- cable ties

- gel type grease (or vaseline)

NOTE: Be sure your hands are clean

the whole time. Clean them at each step and keep a rag and leather cleaner

around because you WILL get your fingers dirty.

Rear Panels

To remove the upper panel on the two part comfort seats you

push the panel straight down while pulling outward at the bottom.

To remove the bottom panel you need to push it sideways at the bottom. Push

toward the centre console and pull out at that side at the same time. Then push

toward the door and pull out at that side.

Once removed you will find two clips on each of the lower and upper panels

(arrowed above) that will respond well to a small amount of 'hot melt' to stop

them rattling.

Plastic Covers above Seat Rails

With the seat raised as high as high as

possible, remove the side covers by first undoing the small allen key socket on

both sides at the front. Then slide the plastic back first, then once the back

end pivots loose from the slot, slide the cover forward and it should remove off

of the seat frame altogether. A point of plastic noise is where this cover goes

around the seat belt bolt at the back and a little velcro fitted inside the rear

of this cover can fix that.

Two rear covers snap off, no tools required. Snap the interior side off

first. Exterior side doesn't have snap fittings. They slide out in direction

parallel to the frame rails.

Seat Rails

A common source of 'clicking' is from the bushings (there are

4 of them) where the seat fastens to the lower rails. You will see the arms

coming down from the seat to the seat rails. At the pivit points there is a Torx

bolt through each of them holding them in place. That bushing gets dry and makes

a click as it moves.

Remove each bolt and lightly grease underneath it. Replace and tighten these

and all other bolts.

Note - do not remove both front bushings at the same time as it is very

difficult to get re-aligned should you happen to move the motors in the mean

time.

Underneath

With the various motors and cables under the seat, the

judicious use of velcro (around the frames onto which some of the plastic bits

clip), foam (inside the plastic surrounds) and hot melt will eliminate a lot of

potential clicks and squeaks.

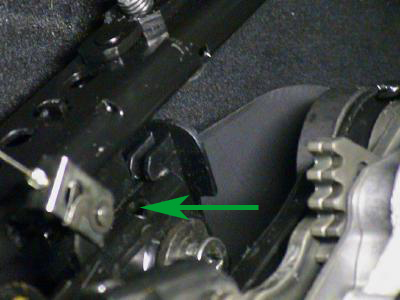

One particular item for attention is the pivot pin (arrowed above) for the

seat belt cable tensioner. Accessed from the rear floor, a slight amount of hot

melt (but don't let it drop onto the carpet) can stop an annoying rattle.

Seat Back

Removal of the seat back is quite straightforward and lubing

the bushings, and installing the sliding jaws can make a big difference.

To separate the seat back/top look for the two green latch locks (above) and

pull them out. Then press the latches down and pull the seat top up. You might

need to cut the cable ties that hold the power and air to give you enough slack.

To press the latches down two screw drivers works great. With the latches

released you can pull the seat back up - but do not stretch the cables.

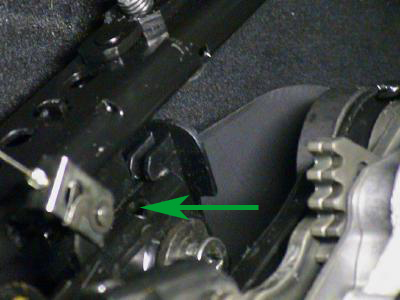

The jaws fit within the seat back at the point where the arms (above) fit in.

If you look carefully you will find two thin metal guides through which the arm

goes. The jaws goes on the outer of these two guides for each arm.

Before replacing the arm in the seat, lube the whole arm with some grease,

especially at the wear points as obvious in the above picture.

Also make sure that when you fasten all the wiring in place and that you

leave enough slack at each tie wrap so that the wire can move without chaffing.